In an interview with New Zealand Trade & Enterprise, Aleph founder Emma Peters talks about closing the loop, take-back schemes and the Aleph mission to design the plastic out of packaging.

Why is ‘closing the loop’ important?

Through my years in the beauty industry, as a make-up artist, I ended up with drawers and drawers full of products. It gutted me how they would just accumulate. I’d never want to throw anything out because I couldn’t bear putting all that waste into landfill.

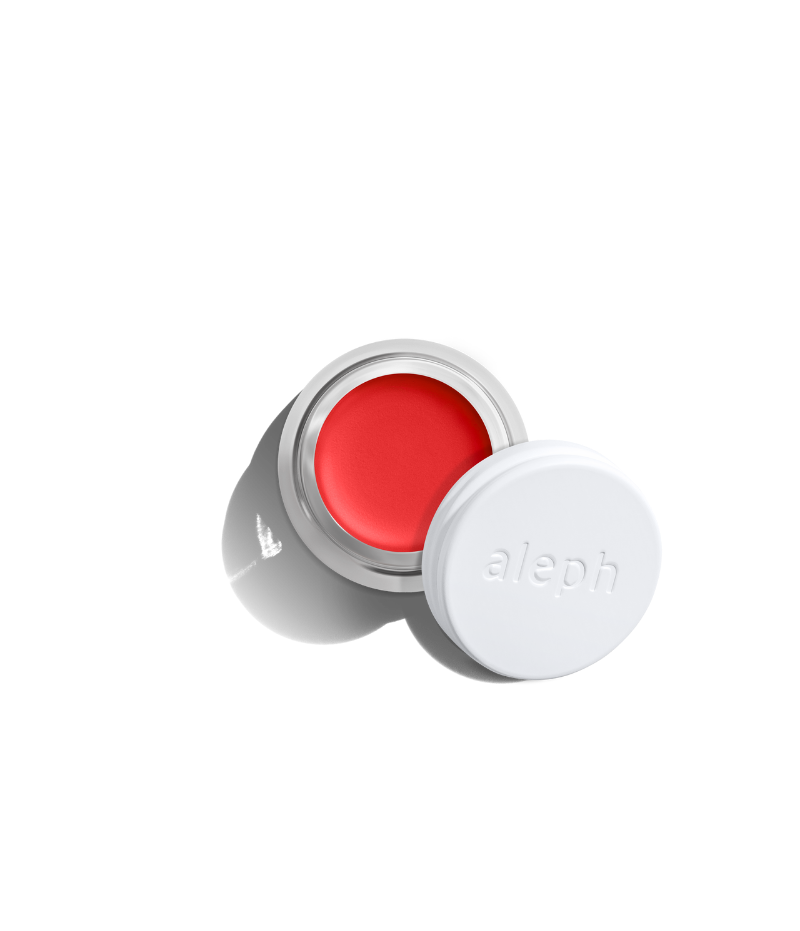

So, in building my own brand, I felt it was really important to use the most sustainable packaging possible. For me personally, I wanted to ensure I wasn’t putting more plastic into landfill. Choosing glass and aluminium as our primary packaging means I can take control of closing the loop and help feed those materials into their next life.

What are the challenges around steering clear of plastic packaging?

There are many reasons why plastic is an obvious packaging choice. It’s cheap. It’s readily available. It’s always the same, from one container to the next. With glass, there are so many anomalies. Each container is going to weigh something slightly different. Each has a different fill volume.

Whether glass is transparent or opaque is another issue. Transparent glass is easy to recycle, but it’s not always compatible with beauty products. These often require opaque glass because they are not light stable, or not heat stable. So, we had to specially formulate our products to cope with being in a transparent container.

Using heavy glass packaging also makes it more expensive to import the packaging into New Zealand, and export our products out.

I'm currently in the process of designing out a tiny piece of plastic that would normally be in one of our packaging components. And we've come up with this beautiful, amazing design. It's stunning. But it's 20 times more expensive than what can be achieved with plastic.

How does your take-back scheme work?

We have collection points at our retailers throughout the country and we give customers the opportunity to send products back to us when they’ve collected enough. Then, we dismantle everything in-house and find the correct recycling stream for each component.

For our glass jars, we worked with the Glass Packaging Forum to get funding towards an industrial cleaning machine. That means we can keep jars in circulation for as long as possible: taking them back, cleaning them, putting product back into them.

When they do reach the end of their lives – when they’re chipped or cracked – we take them to another partner who crushes them down into sand. That sand gets used in the likes of pool filters and racetracks. This ensures our jars are going onto another life and not ending up in landfill.

Can you use take-back schemes in export markets?

For exporters, take-back schemes will look different depending on the market you’re in. We partnered with Pact Collective in the US, a non-profit initiative set on closing the loop for all beauty packaging.

Their take-back scheme works much the same as ours in New Zealand, but on a much greater scale and for many brands. They have a sorting facility in New York, which – fortunately – is where our first US retailer is.

Any advice for businesses moving towards more sustainable packaging?

Start now and work towards the best result. You might not be able to achieve that immediately, but it’s a journey. We started talking to a packaging supplier two years ago about what we wanted, and their answer was, “nope, we can't do that.” But I chipped away. And now they are doing it for us. We had to find a different stopgap for the meantime, but we got there.

My hope is that more companies will start thinking to the nth degree of what is possible in sustainable packaging, demanding this or that of manufacturers. Getting manufacturers really thinking outside of the box. If we can get more people asking for different solutions, the result will be more options. This will bring prices down and make sustainable packaging a lot more achievable for everybody.

Credit: NZTE

Read the original article here.

BACK

BACK