It’s no secret that the beauty industry has a long way to go when it comes to sustainable options and zero-waste systems.

From watering down products to convince buyers that they’re getting more, to only offering makeup in single-use packaging, the cosmetics world is riddled with inefficiencies.

Some products may advertise themselves as “refillable”, yet their packages are made with virgin, non-recyclable plastic. In today’s overwhelming beauty industry, it can be frustrating to find products that are both effective and ethically-created.

At Aleph, our vision is to offer a truly sustainable option that also supports healthy skin. With eco-friendly packaging and efficient formulas to maximise use, our collection is designed to reduce waste without compromising quality or luxury.

Using makeup to the last drop

Nothing’s more frustrating than throwing away a perfectly good foundation because you just can’t squeeze out the last bit from the tube.

The mainstream beauty industry has normalised product waste as an inevitable part of the packaging process – whether it’s the stubby end of an eyeliner pencil or the plastic-covered end of a lipstick tube.

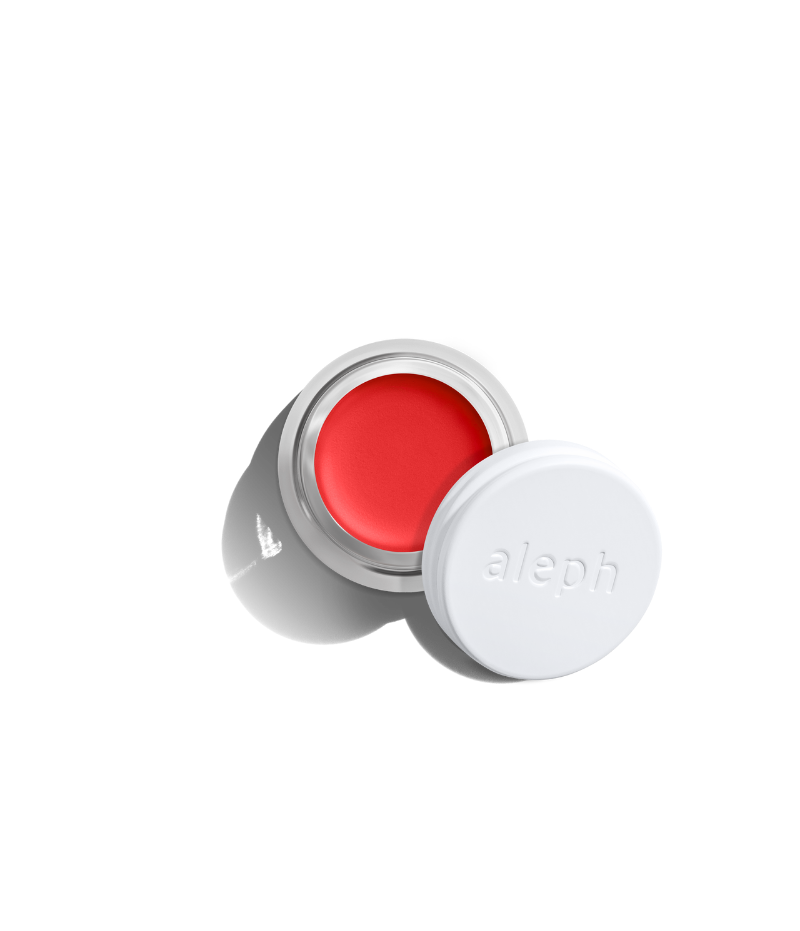

By offering concentrated formulas in accessible packages, Aleph products are designed to allow customers to use makeup down to the last drop.

Conscious packaging

It’s not easy to find alternatives to single-use plastics for makeup. Plastic has been used to package beauty products since the 1950s and is a cheap, effective and malleable solution.

Unfortunately, nearly all the plastic used to package beauty products isn’t recycled or reused, often because it can’t be properly cleaned out and is too small to be picked up by curbside recycling sorting systems. Globally, the beauty industry recycles less than 9% of the 146 million tonnes of plastic produced every year.

While it’s a small step forward on a worldwide scale, Aleph is committed to reducing plastic dependence wherever possible.

We choose glass jars and aluminum lids over plastic tubes, and source paper-based boxes instead of plastic casings. Considering sustainability is a constant challenge, and we continue to look for better options across our entire collection.

Plastic is used where there are no other sustainable options available, and we do our utmost to find the best solutions possible that also meet our high hygiene and performance standards.

Once an Aleph product has been used completely, it can be easily rinsed and returned as part of our circular initiative to reuse and repurpose packaging.

Minimising water-based products

Water is the most common ingredient found in mainstream cosmetics. A typical beauty product contains 60% to 85% water with conventional foundation being on the higher end.

From a sustainability perspective, water-filled products require larger packaging that’s difficult to clean and nearly impossible to recycle. Concentrated formulas, meaning products without water, can help reduce packaging sizes, don’t require plastic squeezable tubes, and can help save water overall.

From a health and consumer perspective, concentrated products are more efficient and effective. Adding water to makeup may dilute the active ingredients in cosmetic formulas, which means less-effective skincare benefits. By choosing only high quality natural oils, butters, and extracts, concentrated formulas work more efficiently, meaning you get more with less.

Take our award-winning Concealer/Foundation, for example. While the glass jar may look like a smaller amount of product than a typical tube of foundation, the concentrated formula means very little product is needed to achieve effective and beneficial results.

We also know that every person’s skin needs and foundation preferences are different. Concealer/Foundation is designed with compatibility in mind, allowing the wearer to mix the formula with Serum/Primer or Radiance Balm to achieve the desired texture and consistency.

Our vision at Aleph is to embrace conscious design that promotes skin health while also reducing waste. We choose to create concentrated makeup products to help reduce packaging sizes, and allow for more control and flexibility when it comes to application.

We’re here to help! If you have any questions after reading this article, please contact us.

BACK

BACK